Projects

Basis of Design

- Turnkey solution,

- Safety and Environmental protection,

- Shortest return of investment,

- Flexible equipment easily adaptable to further types of munitions,

- Scalable processes for further capacity increase with minimum investment,

- Mobile / Transportable equipment,

- Proved and reliable technologies,

- Best Available Technologies for minimum investment,

- Recycling, recovery, and reuse of energetic and inert materials

- Low exploitation and maintenance costs.

- General guidance according NATO STANAG 4518.

- Directive 2010/75/EC regarding pollution prevention and control.

- Directive 2008/98/EC regarding waste.

- Directive 2008/1/EC on Integrated Pollution Prevention and Control.

- Directive 2008/50/EC on Ambient Air Quality and Cleaner Air.

- DA PAM 385 64 US Dept. of Army standards.

- NATO Standard AASTP -1 (Ed B Ver. 1, Dec15) regarding Safety distances and quantities for the storage of military Ammunition and Explosives.

Demilitarization Systems Requirements

- Unpacking and manual disassembly unit,

- Fuze removal – fuze reduction,

- Energetic Material Extraction Equipment,

- Thermal Treatment

- Rotary Kiln,

- Rotary Kiln Gases Filtering,

- Propellants Incineratıon Facility,

- Flashing Furnace

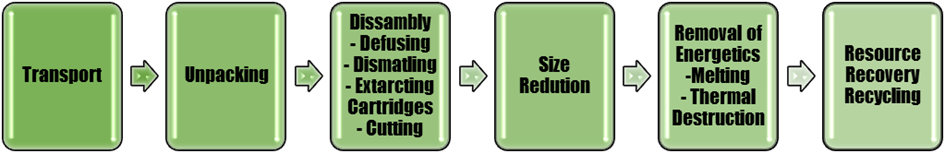

Demilitarization Process

System Specs

- Flexible equipment easily adaptable to further types of munitions

- Scalable processes for further capacity increase with minimum investment

- Mobile / Transportable equipment

- Minimum necessary automation level to ensure productivity without compromising flexibility

- Design, construction, transportation to the receiving location, assembly, run-up, commissioning and operations start full assistance.

- Training for operators, management, health and safety, quality and maintenance personnel,

- Mobile demilitarization good capacities with low investment, short deployment time and complete and mobility.

- Analysis of the potential risks and the application of preventive measures to minimize hazards.

- This same risk assessment process is implemented thoroughly in every stage of work performed at our customer’s facilities worldwide.

- The DS’s solution is focused on Investment Return through the Recovery for re-use of energetic and inert materials, and Economic Viability in the short and long term, seeking facilities with applicability to future munitions and scalability with minimal future investment thanks to our concept of a transportable demilitarization plant.

- Environmental management of projects, design and construction of equipment complying with applicable legal and regulatory norms (EU), and best practices, including in scope all aspects related with end-users’ requirements and constraints.

Demir Savunma (DS) Recovery, Reuse and Recycling (R3 ) Applications

- Scrap Metal Recovery

- One of DS’s resource recovery is the reuse of scrap metal from munitions casings. The scrap metal is safe for reuse. ‘’Flashing’’ is used to remove traces of energetic materials or toxic substances from scrap metal before it is sold. This involves the heat treatment of the metal at approximately 400ºC and flashing furnace is used for the process. Before scrap metal can be released to commercial use, DS provides ‘’Free from Explosives’’ certificates to be met customer’s requirements.

- Energetics Recovery

- DS has developed a resource recovery and reuse (R3) plan for explosive waste. Some basic features are;

- First, the safety of all personnel involved in the processes is ensured.

- Second, the processes that we have improved which enables recover valuable energetic materials for reuse and/or produce high-value by-products.

- Third DS has well-trained technical experts can conduct safely energetics recovery process.

- Forth, our processes are environmentally safe, i.e., no discharge of toxic materials to the environment – ground, water or air

- DS has developed a resource recovery and reuse (R3) plan for explosive waste. Some basic features are;

- One of DS’s potential reuse application is for recovered energetics to be used in new munitions. DS melt out technique meets the qualification requirements for new explosives. This is likely to be most practical for high value explosives such as TNT.

- In addition, energetic materials removed by DS melt out technique can be reused as commercial explosives rather than destroyed. DS’s reclamation, reuse and/or recycling of explosives applications saves a lot of money versus the production of new material. These savings do not include the intangible environmental impact mitigation achieved by not destroying explosives by burning. Moreover, the use of reclaimed materials in lieu of new materials results insignificant time and effort reductions as well as negating the addition of materials to an already overburdened demilitarization stockpile.